- Home Page

- Company Profile

-

Our Products

-

Festoon System

- Rail Festoon System

- C-Rail Festoon System

- Cable Festoon System

- C Rail Festoon System

- Cable Rail Trolley

- Crane Festoon System

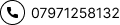

- Cable Trolley

- Festoon Flat Cable

- C Rail System

- Festoon System

- Heavy Duty Festoon System

- Festoon system flat cable

- Festoon System Trolley

- crane C Rail System

- Crane C Track

- Heavy Festoon System

- Curve C Rail Festoon System

- Double Decker Cable Trolley

-

Busbar System

- Enclosed Busbar

- Pin Joint Bus Bar System

- Overhead Crane Busbar

- Central Power Feed Kit

- EOT Crane Current Collector

- Shrouded Dsl Busbar System

- Eot Crane Busbar System

- Aluminium Bus Bar System

- Copper Shrouded Dsl Busbar System

- Dsl Busbar Towing Arm

- Copper Jointer

- Copper Shoe With Cover

- Insulated Shrouded Dsl Conductor Bus Bar

- Current Collector 125a

- Track Coupler

- Jointless Bus Bar

- Insulated Shrouded Dsl Conductor Bar

- Enclosed Conductor Rail

- Current Collector (60a To 125a)

- Shrouded Bus Bar System

- Pin Joint Shrouded Bus Bar

- Box Type Busbar System

- Copper Conductor Bar

- Busbar For Eot Crane

- Dsl Busbar For Eot Crane

- Dsl Busbar System

- Shrouded Dsl For Crane

- Box Type Busbar

- Busbar Jointer

- Gravity Type Current Collector

- Heavy Conductor Crane Rail

- Bolted Joint Dsl Bus Bar

- Bus Bar Connector

- Resistance Box

- Current Collectors

- Pendant cable

- Crane Equipment

- Wire Rope Hoist

- Master Control

- STACKERS

- Crane Brake

- EOT Crane Limit Switches

- Crane Pendant Station

-

Radio Remote Control

- Wireless Radio Remote

- Crane Radio Remote

- Crane Wireless Remote Controller

- F24-12S Telecrane Remote Control

- Radio Remote Control for EOT Cranes

- Tele Crane Radio Remote Control

- Radio Remote Control System

- Radio Remote Control

- F24-BB Radio Remote Control

- Joystick Remote

- Crane Double Speed Radio remote

- Telecrane Radio Control

- Radio Remote Control for Cranes

- F24-60 Double Joystick Remote Control

- Hoist Radio Remote control

- Crane Remote Control System

- Overhead Crane Remote Control System

- F23-BB Radio Remote Controller

- F24-12D Wireless Remote Controller

- F24-4S Wireless Remote Control

- Crane Radio Remote Control

-

Festoon System

- E - Catalog

- Industrial Cranes

- Contact Us

Crane Electrification System

450.0 INR/Roll

Product Details:

- Core Material Copper/Aluminium

- Number of Conductor 4/5 as required

- Core Number 4/5

- Cable Type DSL Busbar system

- Locking Type Clip/Clamp fixed

- Usage & Applications Overhead cranes, Gantry cranes, EOT cranes, Power supply tracks

- Insulation Double insulation

- Click to View more

X

Crane Electrification System Price And Quantity

- 450.0 INR/Roll

- 20 Roll

Crane Electrification System Product Specifications

- Copper/Aluminium

- DSL Busbar crane electrification system

- 415V

- Clip/Clamp fixed

- Standard (Multi-color coding available)

- Other

- Overhead cranes, Gantry cranes, EOT cranes, Power supply tracks

- Copper/Aluminium with PVC insulation

- Standard/customizable

- 4/5 as required

- Copper/Aluminium

- Galvanized Iron

- Surface mounted/Overhead installation

- Other

- 4/5

- Black/Red/Yellow/Green

- Double insulation

- Solid

- PVC

- High conductivity, Reliable performance, Easy installation, Corrosion resistance

- Flat/Rectangular

- PVC

- DSL Busbar system

Crane Electrification System Trade Information

- GODAWN

- Yes

- Free samples are available

- All India

Product Description

Crane Electrification System

Crane Electrification Shrouded Bus Bar DSL system are used for the electrification of mobile equipment Shrouded bus bar is a safe economical and low maintenance way to solve mobile electrification requirement Systems can be designed to accommodate 60 to 1200 amperes Depending on the application there are various options and accessories that can be custom engineered for your conductor bar system Portions of the system can be preassembled at the factory to help ease installation Conductor bar can be found on overhead crane runways hoists trolleys conveyors port cranes and people movers

- Cover with ultra violet additive for outdoor sun locations

- High temperature cover 280F for all conductors

- Stainless steel conductors in for corrosive atmospheres

- Epoxy coated stainless steel and insulated hangers for wet an corrosive atmospheres

- Factory built expansion sections and anchors for expansion control

- Factory bent curved conductor sections systems

- A variety of covers for matching competitive systems

- Heated conductor systems for ice prevention on outdoor systems or freezer storage

- Totally enclosed covers with flap for airborn contaminants indoor outdoor versions

- Bare conductors available for extreme heat applications

- Special longwear collector brushes for systems

Our products are used in following Industries

- Crane manufacturers

- Heavy industries

- Steel industries

- Metal industries

- Indian railways

- Public sector undertaking

- Automobile industries

- Power plants

- Docks ports

- Exports

Reliable Performance in Challenging Environments Designed with high-quality materials, our DSL Busbar System offers exceptional fire, corrosion, and humidity resistance. It maintains dependable operation in both indoor and outdoor settings, even at high humidity levels up to 95%. The rugged construction and double insulation ensure uninterrupted power delivery for critical crane applications.

Flexible Configurations and Easy Installation The system can be customized in length, size, and conductor shape (flat or rectangular) for unique project demands. Installation is straightforward using brackets or suspension fittings, while the surface-mounted or overhead design allows adaptability for a range of crane electrification scenarios. Multi-color coding and clear connector colors enhance maintenance and safety procedures.

Long-Term Value and Reduced Downtime Built to last, the DSL Busbar system offers a service life up to 10 years, supported by high dielectric and tensile strength. The corrosion-resistant, low-impedance design minimizes power losses and maintenance frequency, improving operational efficiency and reducing costly downtime.

FAQs of Crane Electrification System:

Q: How does the DSL Busbar system ensure safety during crane operation?

A: The DSL Busbar system is equipped with a double PVC insulation layer, high dielectric strength, fire and corrosion resistance, and protection class options up to IP44. This comprehensive protection ensures safe and reliable power transmission for cranes, even in demanding industrial environments.Q: What is the installation process for this crane electrification system?

A: Installation is designed for simplicity and flexibility. The system is mounted using brackets or suspension fittings and can be installed surface-mounted or overhead, depending on your facilitys requirements. Clip or clamp locking options further streamline secure installation.Q: When is it recommended to perform maintenance on the busbar system?

A: With proper installation, the DSL Busbar system requires only periodic maintenance, such as routine visual inspections, tightness checks on connectors, and cleaning to remove dust or debris. Regular maintenance ensures a service life of up to 10 years.Q: Where can the DSL Busbar system be used effectively?

A: The system is suitable for both indoor and outdoor environments, making it ideal for overhead cranes, gantry cranes, EOT cranes, and power supply tracks in warehouses, factories, and assembly plants.Q: What are the benefits of choosing this DSL Busbar system for crane applications?

A: Key benefits include high conductivity and reliable power delivery, easy customization, robust environmental resistance, minimal maintenance needs, long service life, and enhanced safety through color-coded connectors and insulation. This results in efficient and uninterrupted crane operations.Q: How does the system cope with high humidity and temperature variations?

A: The DSL Busbar system is engineered to handle humidity levels up to 95% and operates efficiently across temperatures from -20C to +70C. Its corrosion-resistant and insulated structure prevents moisture-related degradation and electrical faults.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Crane Equipment' category

|

CMK ELECTRO POWER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |