- Home Page

- Company Profile

-

Our Products

-

Festoon System

- C Rail Festoon System

- C Rail System

- Cable Trolley

- Festoon system flat cable

- Rail Festoon System

- Festoon Flat Cable

- Crane Festoon System

- Heavy Duty Festoon System

- Festoon System Trolley

- Cable Festoon System

- Cable Rail Trolley

- crane C Rail System

- Crane C Track

- Heavy Festoon System

- Curve C Rail Festoon System

- C-Rail Festoon System

- Festoon System

- Double Decker Cable Trolley

-

Busbar System

- Gravity Type Current Collector

- Copper Jointer

- Eot Crane Busbar System

- Heavy Conductor Crane Rail

- Busbar Jointer

- Insulated Shrouded Dsl Conductor Bus Bar

- Central Power Feed Kit

- Enclosed Busbar

- Dsl Busbar For Eot Crane

- Shrouded Dsl Busbar System

- Enclosed Conductor Rail

- Copper Shrouded Dsl Busbar System

- Jointless Bus Bar

- Shrouded Dsl For Crane

- EOT Crane Current Collector

- Bus Bar Connector

- Dsl Busbar Towing Arm

- Box Type Busbar System

- Current Collector 125a

- Box Type Busbar

- Copper Shoe With Cover

- Current Collector (60a To 125a)

- Pin Joint Shrouded Bus Bar

- Shrouded Bus Bar System

- Dsl Busbar System

- Track Coupler

- Aluminium Bus Bar System

- Bolted Joint Dsl Bus Bar

- Copper Conductor Bar

- Pin Joint Bus Bar System

- Overhead Crane Busbar

- Insulated Shrouded Dsl Conductor Bar

- Busbar For Eot Crane

- Resistance Box

- Current Collectors

- Pendant cable

- Crane Equipment

- Wire Rope Hoist

- Master Control

- STACKERS

- Crane Brake

- EOT Crane Limit Switches

- Crane Pendant Station

-

Radio Remote Control

- Tele Crane Radio Remote Control

- Crane Remote Control System

- Radio Remote Control for EOT Cranes

- Crane Radio Remote

- Wireless Radio Remote

- Crane Double Speed Radio remote

- Crane Wireless Remote Controller

- F24-12S Telecrane Remote Control

- Overhead Crane Remote Control System

- Radio Remote Control System

- F24-BB Radio Remote Control

- Joystick Remote

- F24-12D Wireless Remote Controller

- Radio Remote Control for Cranes

- F24-4S Wireless Remote Control

- Telecrane Radio Control

- F23-BB Radio Remote Controller

- Crane Radio Remote Control

- Radio Remote Control

- F24-60 Double Joystick Remote Control

- Hoist Radio Remote control

-

Festoon System

- E - Catalog

- Industrial Cranes

- Contact Us

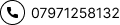

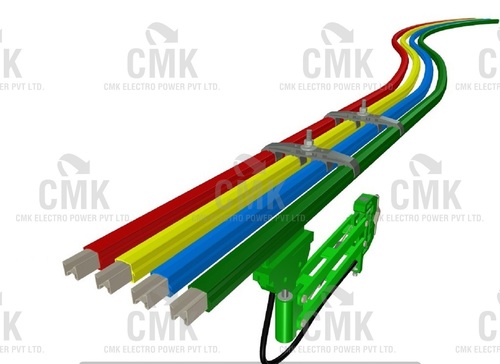

Shrouded Bus Bar System

1600.0 INR/Meter

Product Details:

- Mounting Type Suspended / surface mounting

- Efficiency Up to 98%

- Protection Level IP 23 or higher

- Humidity 0-95% RH, non-condensing

- Input Current Up to 1250A (depending on model)

- Phase 3 Phase / Single Phase (customizable)

- Function Safe and efficient current transmission to mobile equipment

- Click to View more

X

Shrouded Bus Bar System Price And Quantity

- 1600.0 INR/Meter

- 20 Meter

Shrouded Bus Bar System Product Specifications

- Overhead cranes, hoists, conveyors, material handling systems

- Up to 1250A (depending on model)

- 0-95% RH, non-condensing

- Suspended / surface mounting

- 3 Phase / Single Phase (customizable)

- Included mounting brackets and joint covers

- IP 23 or higher

- Up to 98%

- Safe and efficient current transmission to mobile equipment

- Electric

Shrouded Bus Bar System Trade Information

- GODAWN

- Cheque

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- AS PER REQUIREMENT

- Africa, South America, Asia

- All India

Product Description

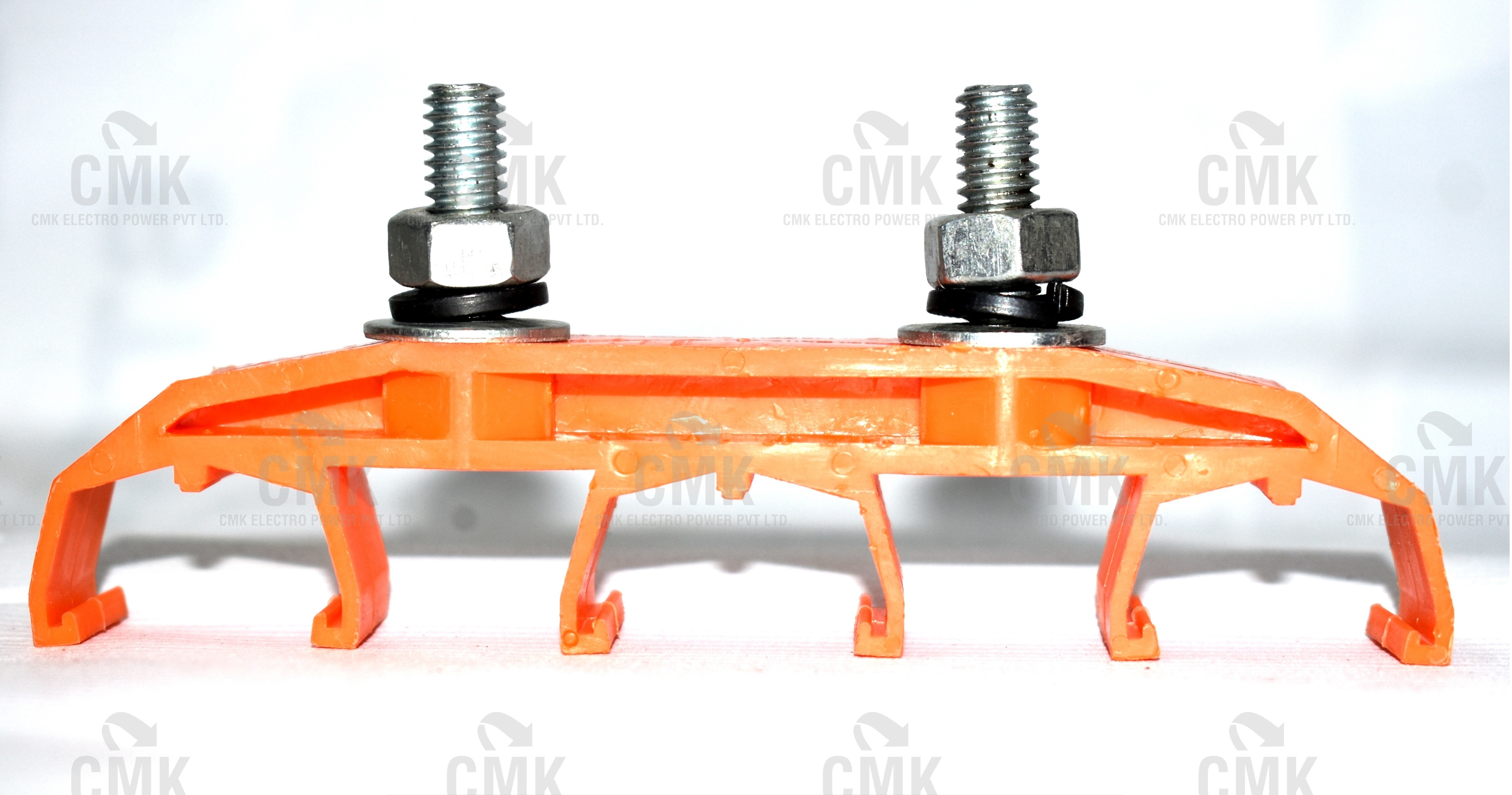

Shrouded Bus Bar System

Having huge industrial expertise in this domain we have been affianced in manufacturing exporting and supplying an optimum grade Shrouded Bus Bar System Offered bar system is manufactured using top notch quality raw materials and pioneering techniques as per set industry standards under the guidance of adroit experts Owing to the features like low maintenance and corrosion resistance the provided system is extensively demanded among the customers Besides this Shrouded Bus Bar System can be availed by our valuable patrons at reasonable rates

Features

- Compact design

- Sturdiness

- Highly durable

- Fine finish

- Amperage 60Amp1200Amp

- GI 60 A to 125A

- Aluminium125A to 500A

- Copper jointless25A to 200A

- Copper160A to 1200A

- Length 45 m

Advanced Safety and Compliance

Designed to adhere to IEC 61439 and IS standards, the Shrouded Bus Bar System ensures robust electrical safety, tested for short circuit withstand and consistent flame resistance. Its insulation materials are rated to withstand high temperatures and harsh conditions, coupled with standardized phase color identification for clear and safe installation.

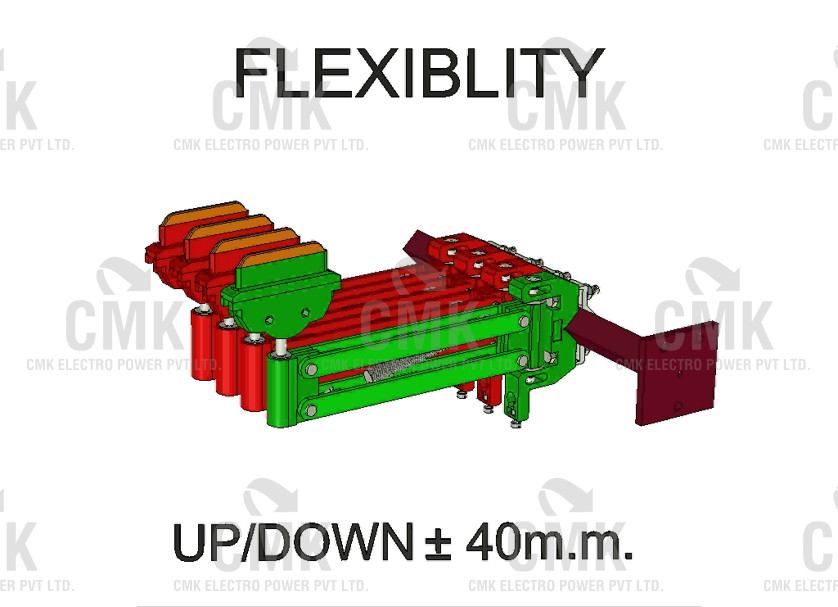

Flexible Application and Customization

This system accommodates a range of applications, with 3, 4, or 5 pole options and the capacity for up to 1250A at 690V AC. Its dimensions can be customized to meet unique project requirements, ensuring compatibility with various overhead cranes, hoists, and conveyor systems. Installation is adaptable via suspended or surface mounting methods.

Ease of Use and Maintenance

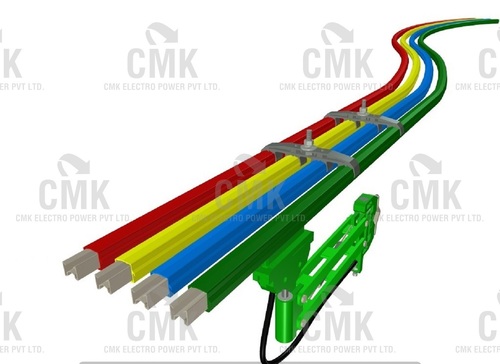

With a modular assembly process, this bus bar system allows for swift installation and straightforward expansion or servicing. Spring-loaded collector trolleys guarantee reliable and uninterrupted power delivery, while easy-access design facilitates routine inspection, reducing downtime and maintenance costs.

FAQs of Shrouded Bus Bar System:

Q: How is the Shrouded Bus Bar System installed and what makes the process efficient?

A: The system is designed for quick and modular assembly, utilizing customizable dimensions and mounting options (suspended or surface). Included accessories, such as brackets and joint covers, streamline the installation process, making it suitable for new setups or upgrades with minimal downtime.Q: What environments is the copper DSL bus bar system suitable for, and how is it protected against environmental challenges?

A: Engineered for both indoor and outdoor use, the system features flame-retardant, anti-corrosive insulation and hardware, protecting it from humidity (up to 95% RH, non-condensing), temperature extremes (from -30C to +80C), and other harsh conditions.Q: When should a shrouded bus bar system be chosen over traditional exposed busbars?

A: A shrouded bus bar system is ideal when enhanced electrical safety, environmental protection, low maintenance, and compliance with international standards are neededespecially in dynamic applications like moving equipment or harsh industrial environments.Q: What are the benefits of using spring-loaded collector trolleys for current collection?

A: Spring-loaded collector trolleys ensure consistent contact and stable current collection from the copper conductors, enabling efficient and reliable power transmission to mobile machinery even during continuous or high-speed movement.Q: Where can this bus bar system be typically applied?

A: This system is widely used in overhead cranes, hoists, conveyors, and various material handling systems in industrial settings where a reliable and safe power source for mobile equipment is essential.Q: How does the system comply with electrical standards and ensure operational safety?

A: The entire assembly conforms to IEC 61439 and relevant IS standards, with features including phase color coding, flame-retardant insulation, and tested short circuit withstand capacity, delivering advanced safety and regulatory compliance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Busbar System' category

|

CMK ELECTRO POWER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |