- Home Page

- Company Profile

-

Our Products

-

Festoon System

- C Rail Festoon System

- C Rail System

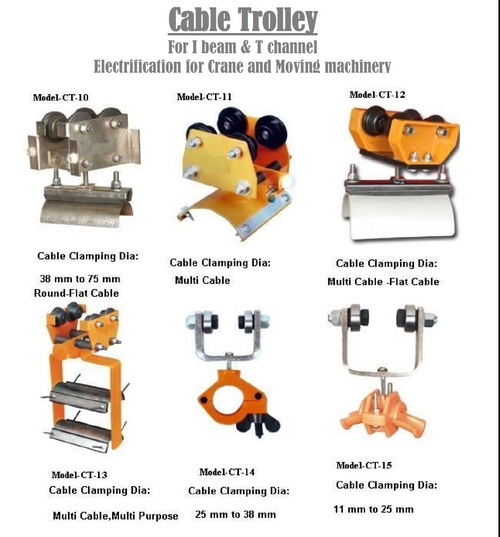

- Cable Trolley

- Festoon system flat cable

- Rail Festoon System

- Festoon Flat Cable

- Crane Festoon System

- Heavy Duty Festoon System

- Festoon System Trolley

- Cable Festoon System

- Cable Rail Trolley

- crane C Rail System

- Crane C Track

- Heavy Festoon System

- Curve C Rail Festoon System

- C-Rail Festoon System

- Festoon System

- Double Decker Cable Trolley

-

Busbar System

- Gravity Type Current Collector

- Copper Jointer

- Eot Crane Busbar System

- Heavy Conductor Crane Rail

- Busbar Jointer

- Insulated Shrouded Dsl Conductor Bus Bar

- Central Power Feed Kit

- Enclosed Busbar

- Dsl Busbar For Eot Crane

- Shrouded Dsl Busbar System

- Enclosed Conductor Rail

- Copper Shrouded Dsl Busbar System

- Jointless Bus Bar

- Shrouded Dsl For Crane

- EOT Crane Current Collector

- Bus Bar Connector

- Dsl Busbar Towing Arm

- Box Type Busbar System

- Current Collector 125a

- Box Type Busbar

- Copper Shoe With Cover

- Current Collector (60a To 125a)

- Pin Joint Shrouded Bus Bar

- Shrouded Bus Bar System

- Dsl Busbar System

- Track Coupler

- Aluminium Bus Bar System

- Bolted Joint Dsl Bus Bar

- Copper Conductor Bar

- Pin Joint Bus Bar System

- Overhead Crane Busbar

- Insulated Shrouded Dsl Conductor Bar

- Busbar For Eot Crane

- Resistance Box

- Current Collectors

- Pendant cable

- Crane Equipment

- Wire Rope Hoist

- Master Control

- STACKERS

- Crane Brake

- EOT Crane Limit Switches

- Crane Pendant Station

-

Radio Remote Control

- Tele Crane Radio Remote Control

- Crane Remote Control System

- Radio Remote Control for EOT Cranes

- Crane Radio Remote

- Wireless Radio Remote

- Crane Double Speed Radio remote

- Crane Wireless Remote Controller

- F24-12S Telecrane Remote Control

- Overhead Crane Remote Control System

- Radio Remote Control System

- F24-BB Radio Remote Control

- Joystick Remote

- F24-12D Wireless Remote Controller

- Radio Remote Control for Cranes

- F24-4S Wireless Remote Control

- Telecrane Radio Control

- F23-BB Radio Remote Controller

- Crane Radio Remote Control

- Radio Remote Control

- F24-60 Double Joystick Remote Control

- Hoist Radio Remote control

-

Festoon System

- E - Catalog

- Industrial Cranes

- Contact Us

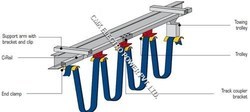

C Rail System

450.0 INR/Piece

Product Details:

- Core Number Multi-core

- Number of Conductor 3 to 7 (configurable)

- Locking Type Spring loaded locking

- Usage & Applications Used in overhead cranes, hoists, conveyor systems

- Conductor Type Stranded

- Cable Type Flat/round cable compatible

- Install Type Suspended rail mount

- Click to View more

X

C Rail System Price And Quantity

- 20 Piece

- 450.0 INR/Piece

C Rail System Product Specifications

- Copper

- Standard sizes available

- Galvanized Steel

- C Rail System offers reliable cable support and smooth trolley movement for power transmission in cranes and moving machinery.

- Round

- PVC

- 4 Meter (m)

- Other

- Suspended rail mount

- High Voltage

- Flat/round cable compatible

- PVC insulation

- FESTOON SYSTEM

- Silver

- Used in overhead cranes, hoists, conveyor systems

- Galvanized Steel/Copper

- Spring loaded locking

- Other

- Galvanized Steel

- Stranded

- Galvanized Steel

- 3 to 7 (configurable)

- Copper

- Metallic

- Multi-core

C Rail System Trade Information

- GODAWN

- Yes

- Free samples available with shipping and taxes paid by the buyer

- All India

Product Description

With the assistance of our industrial expertise in this domain, we have engaged ourselves to manufacture, export and supply supreme grade array of C Rail System. The offered system is used in overhead cranes, port cranes, refuse cranes and other material handling applications. This system is manufactured using top notch quality raw materials and sophisticated techniques as per defined standard under the strict guidance of adroit professionals. Besides, we offer this C Rail System at pocket friendly rates to our precious patrons.

Features:

- Accurate dimension

- Easy installation

- Fine finish

- Strong construction

Reliable and Durable Power Transmission

Designed for robust industrial use, the C Rail System guarantees smooth, dependable cable movement. Its corrosion-resistant finish and armored galvanized steel jacket protect against harsh conditions, ensuring consistent, long-term operation for cranes and moving equipment.

Versatile Configuration for Diverse Applications

Offering customizable dimensions and profiles, this system suits a wide range of cable types and trolley designs. Standard lengths are 4 meters, but options are adaptable to specific requirements. Its suitable for overhead cranes, conveyor systems, and more.

Low Noise and High Safety Standards

Engineered with low-noise trolley movement and IP20 ingress protection, the C Rail System creates a safer, quieter workspace. PVC insulation and copper conductors guarantee excellent dielectric strength and safety across industrial voltage ranges.

FAQs of C Rail System:

Q: How can the C Rail System be installed in industrial settings?

A: The C Rail System can be mounted on ceilings or walls using suspended rail brackets, providing flexibility for various facility layouts. Installation requires securing the rail profile and connecting the trolleys and cables as per the manufacturers guidelines.Q: What types of cables are compatible with the C Rail System?

A: This system supports both flat and round cable configurations, accommodating 3 to 7 stranded copper conductors. The PVC insulation and galvanized steel jacket ensure compatibility and protection for different cable types in demanding environments.Q: When is it ideal to use the C Rail System for power supply applications?

A: The C Rail System is ideal for use in power transmission for cranes, hoists, and moving machinery whenever reliable cable support, smooth trolley motion, and safety are required, especially in environments with high voltage and heavy duty operations.Q: Where can the C Rail System be integrated?

A: It can be integrated in industrial facilities including factories, warehouses, and production linesspecifically wherever overhead cranes, conveyor systems, or material handling equipment require efficient, secure power delivery.Q: What advantages does the C Rail System offer over traditional cable management systems?

A: The C Rail System provides stable, low-noise trolley movement, high load capacity, corrosion resistance, and flexible mounting options. These advantages contribute to improved reliability, reduced maintenance, and enhanced workplace safety.Q: How does the spring-loaded locking mechanism function in the C Rail System?

A: The spring-loaded locking mechanism securely holds the trolley in place on the C-shaped rail, preventing accidental disengagement and ensuring stable operation throughout travel. This enhances safety during high-speed movement and load handling.Q: What process should be followed for maintenance and service of the C Rail System?

A: Regular inspections for wear, proper lubrication of moving parts, and checking for corrosion or loose fittings maintain optimal performance. Following manufacturer recommendations ensures long-term service life and reliability in industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Festoon System' category

|

CMK ELECTRO POWER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |