- Home Page

- Company Profile

-

Our Products

-

Festoon System

- C Rail Festoon System

- C Rail System

- Cable Trolley

- Festoon system flat cable

- Rail Festoon System

- Festoon Flat Cable

- Crane Festoon System

- Heavy Duty Festoon System

- Festoon System Trolley

- Cable Festoon System

- Cable Rail Trolley

- crane C Rail System

- Crane C Track

- Heavy Festoon System

- Curve C Rail Festoon System

- C-Rail Festoon System

- Festoon System

- Double Decker Cable Trolley

-

Busbar System

- Gravity Type Current Collector

- Copper Jointer

- Eot Crane Busbar System

- Heavy Conductor Crane Rail

- Busbar Jointer

- Insulated Shrouded Dsl Conductor Bus Bar

- Central Power Feed Kit

- Enclosed Busbar

- Dsl Busbar For Eot Crane

- Shrouded Dsl Busbar System

- Enclosed Conductor Rail

- Copper Shrouded Dsl Busbar System

- Jointless Bus Bar

- Shrouded Dsl For Crane

- EOT Crane Current Collector

- Bus Bar Connector

- Dsl Busbar Towing Arm

- Box Type Busbar System

- Current Collector 125a

- Box Type Busbar

- Copper Shoe With Cover

- Current Collector (60a To 125a)

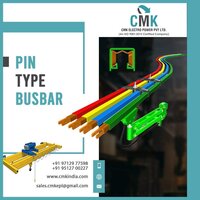

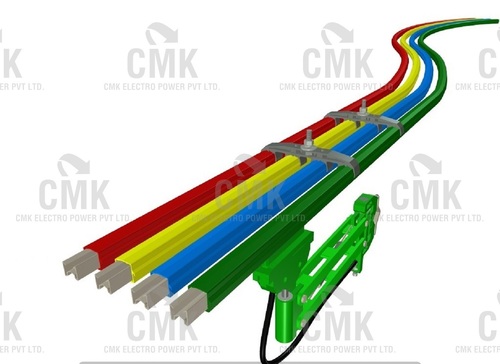

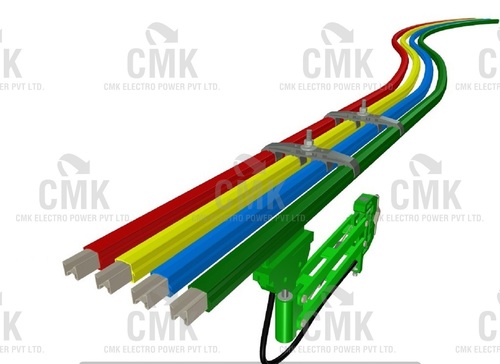

- Pin Joint Shrouded Bus Bar

- Shrouded Bus Bar System

- Dsl Busbar System

- Track Coupler

- Aluminium Bus Bar System

- Bolted Joint Dsl Bus Bar

- Copper Conductor Bar

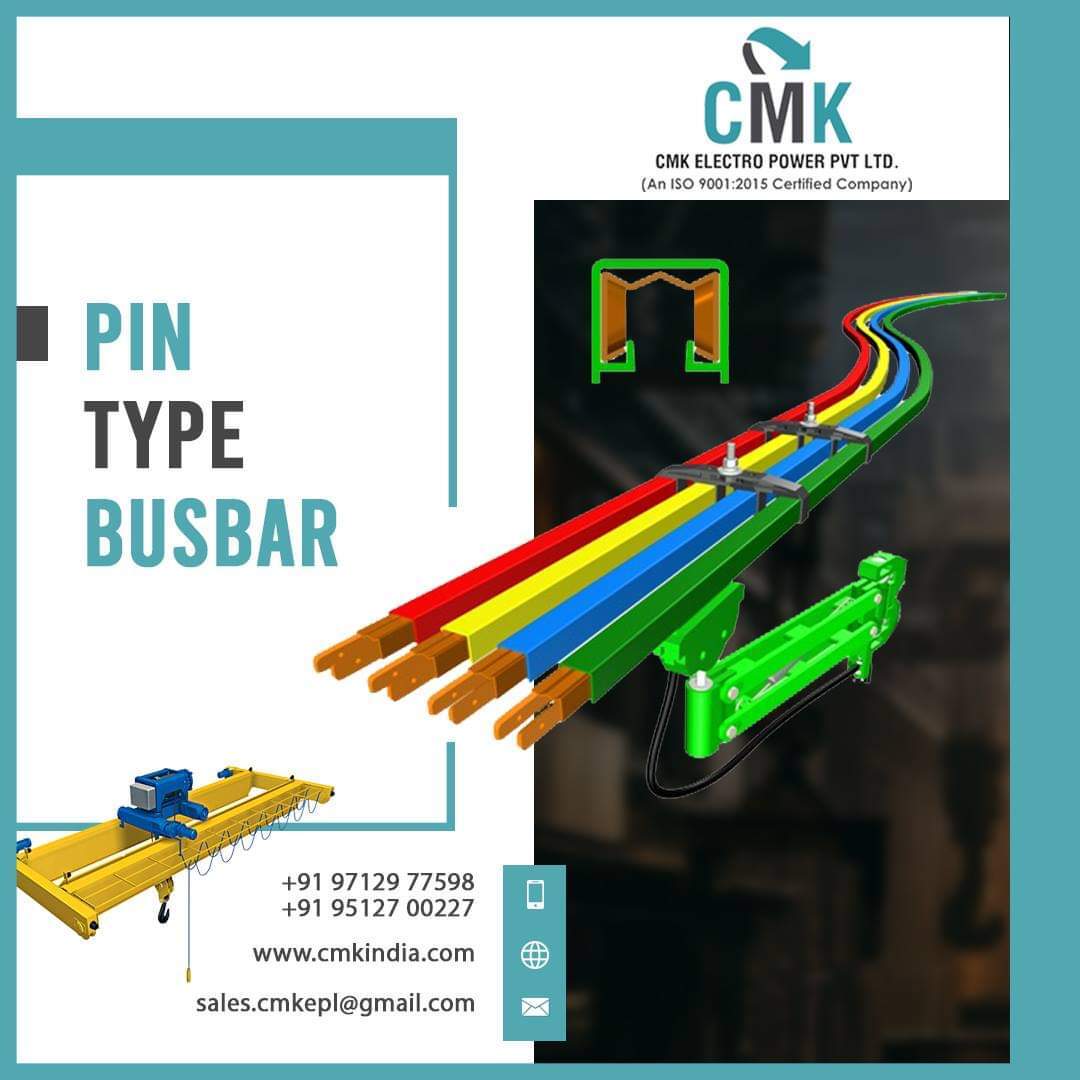

- Pin Joint Bus Bar System

- Overhead Crane Busbar

- Insulated Shrouded Dsl Conductor Bar

- Busbar For Eot Crane

- Resistance Box

- Current Collectors

- Pendant cable

- Crane Equipment

- Wire Rope Hoist

- Master Control

- STACKERS

- Crane Brake

- EOT Crane Limit Switches

- Crane Pendant Station

-

Radio Remote Control

- Tele Crane Radio Remote Control

- Crane Remote Control System

- Radio Remote Control for EOT Cranes

- Crane Radio Remote

- Wireless Radio Remote

- Crane Double Speed Radio remote

- Crane Wireless Remote Controller

- F24-12S Telecrane Remote Control

- Overhead Crane Remote Control System

- Radio Remote Control System

- F24-BB Radio Remote Control

- Joystick Remote

- F24-12D Wireless Remote Controller

- Radio Remote Control for Cranes

- F24-4S Wireless Remote Control

- Telecrane Radio Control

- F23-BB Radio Remote Controller

- Crane Radio Remote Control

- Radio Remote Control

- F24-60 Double Joystick Remote Control

- Hoist Radio Remote control

-

Festoon System

- E - Catalog

- Industrial Cranes

- Contact Us

Bolted Joint Dsl Bus Bar

430.0 INR/Meter

Product Details:

- Humidity Up to 95% Non-Condensing

- Protection Level IP23

- Input Current Up to 2000A (Depending on Model)

- Efficiency High (>98%)

- Phase Three Phase or Single Phase options

- Mounting Type Surface/Overhead Mounting

- Function Current Transmission and Distribution

- Click to View more

X

Bolted Joint Dsl Bus Bar Price And Quantity

- 20 Meter

- 430.0 INR/Meter

Bolted Joint Dsl Bus Bar Product Specifications

- IP23

- High (>98%)

- Up to 95% Non-Condensing

- Joint Bolts, Insulating Covers

- Current Transmission and Distribution

- Electric

- Surface/Overhead Mounting

- Overhead Crane, Material Handling Systems, Industrial Power Distribution

- Up to 2000A (Depending on Model)

- Three Phase or Single Phase options

Bolted Joint Dsl Bus Bar Trade Information

- GODAWN

- Yes

- Free samples are available

- AS PER REQUIREMENT

- All India

Product Description

Bolted Joint Dsl Bus Bar

With the help of our fullfledged production division we are able to offer Bolted Joint DSL Bus Bar for our prestigious clients This bus bar is precisely manufactured by utilizing supreme quality raw materials and latest machinery as per set market norms The offered bus bar is available in numerous specifications to meet the diverse requirements of our clients Moreover it is tested on numerous quality parameters to ensure its flawlessness Besides our provided Bolted Joint DSL Bus Bar is used for the electrification of mobile equipment

Features

- Anticorrosive in nature

- Easy installation

- Dimensional accuracy

- Maximum strength

Technical Data Sheet

- Galvanized Steel Bus bar Copper Bus bar Aluminum Bus bar

- Ampere Capacity 60A 100A 125A 160A 250A 400A 200A 315A

- Impedance mill ohmM 345 276 182 032 028 020 030 028

- DC Resistance Mill ohmsM 342 274 180 031 027 019 026 022

- Standard Conductor Length 45 Mtrs 45 Mtrs 45 Mtrs

- Conductor bar can be found on overhead crane runways hoists trolleys conveyors port cranes and people movers

- Cover with ultra violet additive for outdoor sun locations

- High temperature cover 280F for all conductors

- Stainless steel conductors in for corrosive atmospheres

- Epoxy coated stainless steel and insulated hangers for wet an corrosive atmospheres

- Factory built expansion sections and anchors for expansion control

- Factory bent curved conductor sections systems

- A variety of covers for matching competitive systems

- Heated conductor systems for ice prevention on outdoor systems or freezer storage

- Totally enclosed covers with flap for airborn contaminants indoor outdoor versions

- Bare conductors available for extreme heat applications

- Special longwear collector brushes for systems

Modular and Customizable Design

The DSL busbars bolted joint construction allows for straightforward assembly and flexibility in length, cross-sectional area, and ratings. This modular approach simplifies both large-scale installations and future upgrades. Customization can be requested for specific dimensions, ratings, colors, and connection types, making it suitable for diverse industrial applications and site-specific requirements.

High Performance and Safety

Constructed using galvanized steel, copper, or aluminum, this busbar ensures efficient power transmission while maintaining high corrosion resistance. With insulation class B or C and IP23 protection, your setup benefits from advanced safety measures. The busbar operates over a wide temperature range and in high-humidity environments, making it ideal for various challenging industrial conditions.

Versatile Applications and Easy Installation

Engineered for use in overhead crane systems, material handling, and industrial power distribution, the busbar is designed for surface or overhead mounting. Its modular sections, complete with necessary accessories, enable rapid installation and maintenance, minimizing downtime. The busbar supports both three-phase and single-phase systems, adding to its versatility.

FAQs of Bolted Joint Dsl Bus Bar:

Q: How is the bolted joint DSL busbar installed, and what makes the process user-friendly?

A: Installation is straightforward due to its modular, bolted-joint design. Each section interlocks easily with joint bolts and insulating covers, allowing for quick assembly or replacement. This approach saves both time and labor costs, and the system can be mounted on surfaces or overhead structures.Q: What customization options are available for this DSL busbar system?

A: You can request custom lengths, cross-sectional areas, ratings, and even specific colors to suit your application. Both mechanical dimensions and electrical ratings can be tailored, ensuring seamless adaptation to existing setup requirements or special project needs.Q: When should I choose copper versus aluminum as the contact material?

A: Copper is typically chosen for higher conductivity and better performance in high-current or critical applications. Aluminum offers a more cost-effective solution while still providing excellent electrical properties suitable for many industrial uses. Selection depends on current rating, budget, and project specifications.Q: Where can this bolted joint DSL busbar be used most effectively?

A: This busbar is ideal for industrial environments such as overhead crane installations, material handling systems, and general power distribution setups. Its robust construction and adaptability make it suitable for outdoor and harsh indoor environments.Q: What are the main benefits of choosing this busbar system for industrial applications?

A: Key benefits include high electrical efficiency (>98%), long service life (over 10 years with maintenance), excellent corrosion resistance, and simplified installation. Customizability and robust safety features ensure reliable, long-term operation under demanding conditions.Q: How does the busbar ensure electrical and operational safety during usage?

A: The systems insulation class B or C, along with protective covers and IP23 rating, provides solid electrical safety. These features prevent accidental contact, minimize risk of short circuits, and ensure safe operation in high-humidity or fluctuating temperature environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Busbar System' category

|

CMK ELECTRO POWER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |