- Home Page

- Company Profile

-

Our Products

-

Festoon System

- C Rail Festoon System

- C Rail System

- Cable Trolley

- Festoon system flat cable

- Rail Festoon System

- Festoon Flat Cable

- Crane Festoon System

- Heavy Duty Festoon System

- Festoon System Trolley

- Cable Festoon System

- Cable Rail Trolley

- crane C Rail System

- Crane C Track

- Heavy Festoon System

- Curve C Rail Festoon System

- C-Rail Festoon System

- Festoon System

- Double Decker Cable Trolley

-

Busbar System

- Gravity Type Current Collector

- Copper Jointer

- Eot Crane Busbar System

- Heavy Conductor Crane Rail

- Busbar Jointer

- Insulated Shrouded Dsl Conductor Bus Bar

- Central Power Feed Kit

- Enclosed Busbar

- Dsl Busbar For Eot Crane

- Shrouded Dsl Busbar System

- Enclosed Conductor Rail

- Copper Shrouded Dsl Busbar System

- Jointless Bus Bar

- Shrouded Dsl For Crane

- EOT Crane Current Collector

- Bus Bar Connector

- Dsl Busbar Towing Arm

- Box Type Busbar System

- Current Collector 125a

- Box Type Busbar

- Copper Shoe With Cover

- Current Collector (60a To 125a)

- Pin Joint Shrouded Bus Bar

- Shrouded Bus Bar System

- Dsl Busbar System

- Track Coupler

- Aluminium Bus Bar System

- Bolted Joint Dsl Bus Bar

- Copper Conductor Bar

- Pin Joint Bus Bar System

- Overhead Crane Busbar

- Insulated Shrouded Dsl Conductor Bar

- Busbar For Eot Crane

- Resistance Box

- Current Collectors

- Pendant cable

- Crane Equipment

- Wire Rope Hoist

- Master Control

- STACKERS

- Crane Brake

- EOT Crane Limit Switches

- Crane Pendant Station

-

Radio Remote Control

- Tele Crane Radio Remote Control

- Crane Remote Control System

- Radio Remote Control for EOT Cranes

- Crane Radio Remote

- Wireless Radio Remote

- Crane Double Speed Radio remote

- Crane Wireless Remote Controller

- F24-12S Telecrane Remote Control

- Overhead Crane Remote Control System

- Radio Remote Control System

- F24-BB Radio Remote Control

- Joystick Remote

- F24-12D Wireless Remote Controller

- Radio Remote Control for Cranes

- F24-4S Wireless Remote Control

- Telecrane Radio Control

- F23-BB Radio Remote Controller

- Crane Radio Remote Control

- Radio Remote Control

- F24-60 Double Joystick Remote Control

- Hoist Radio Remote control

-

Festoon System

- E - Catalog

- Industrial Cranes

- Contact Us

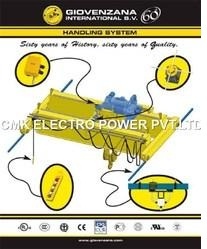

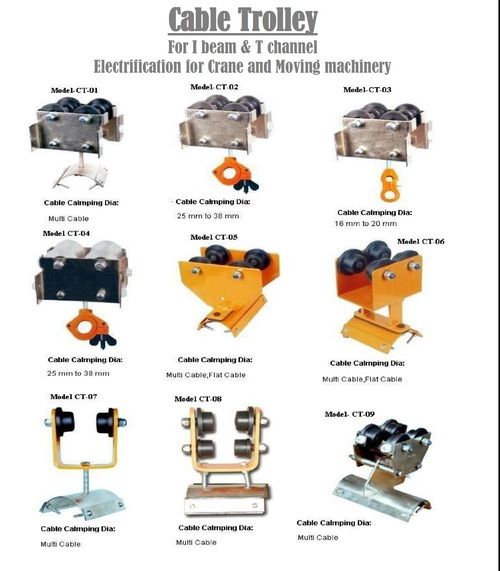

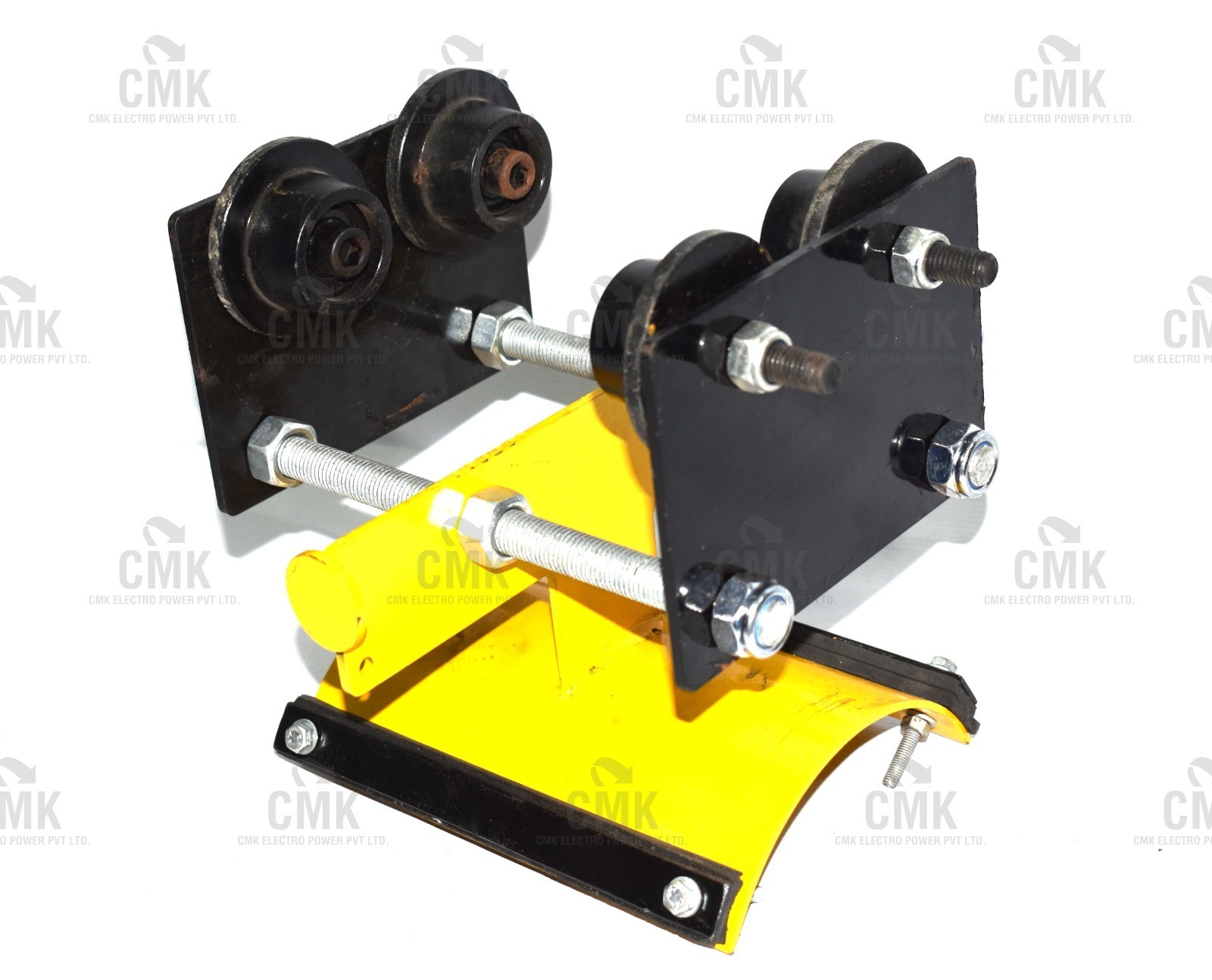

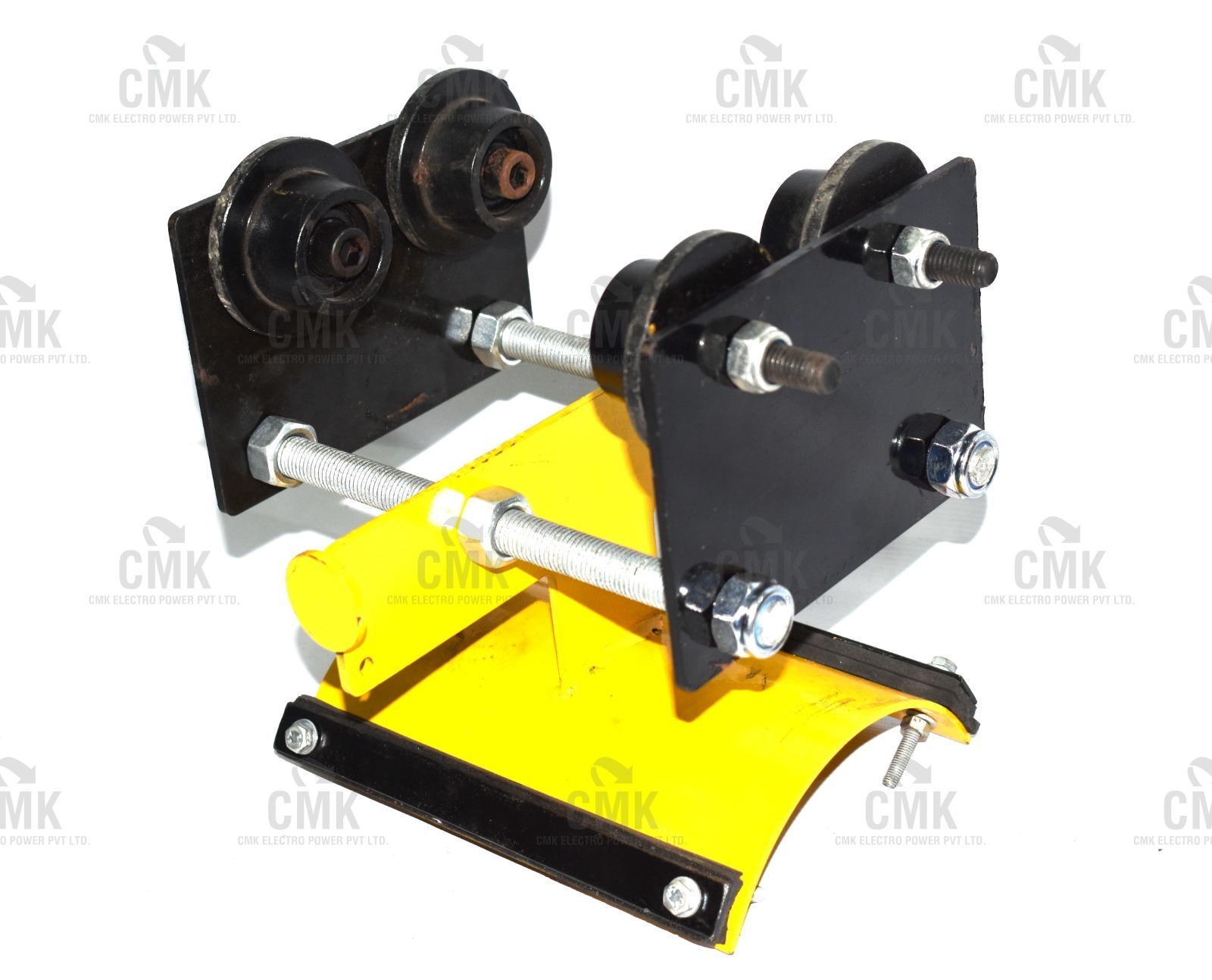

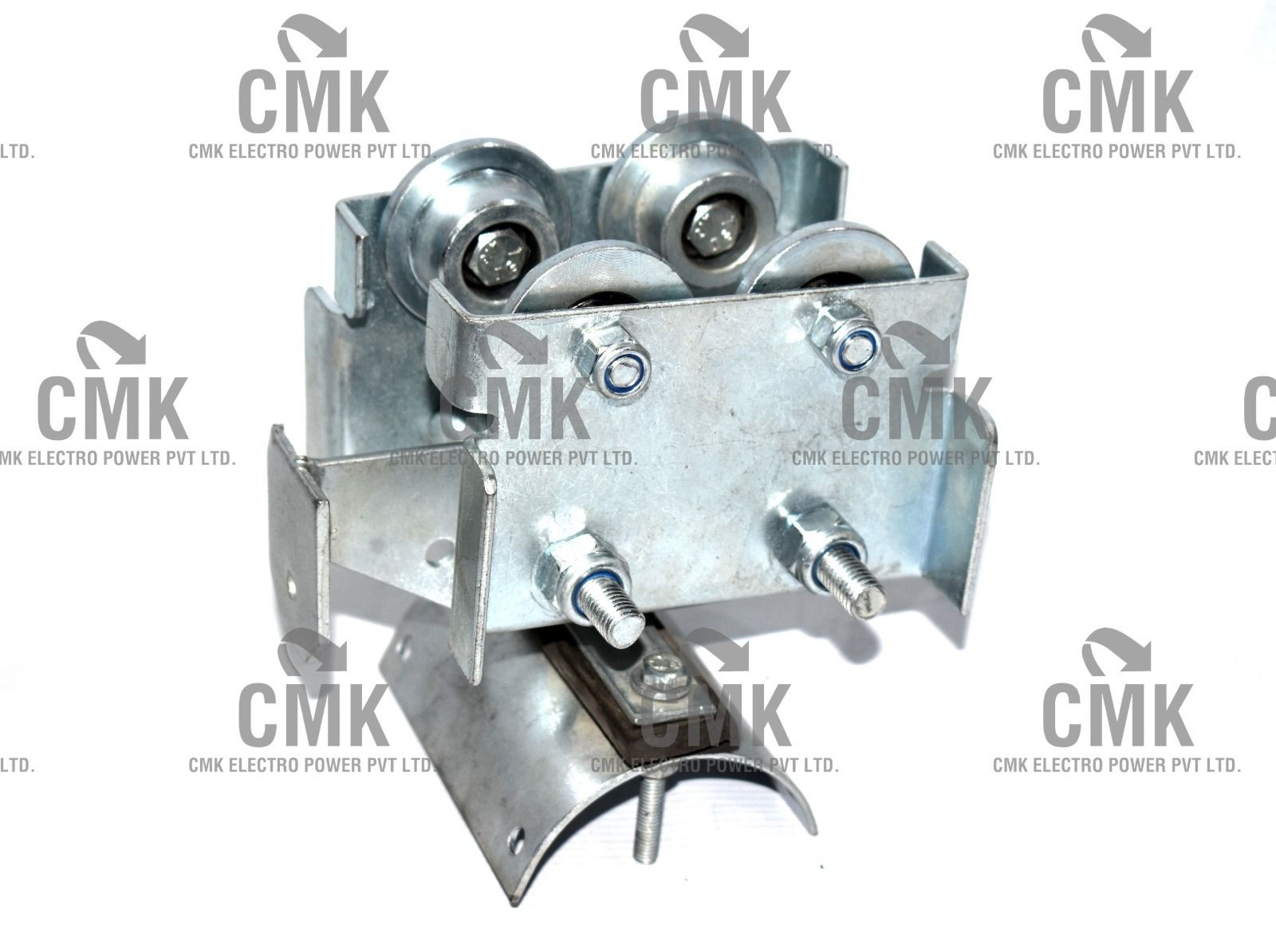

I Beam Cable Trolleys

450.0 INR/Piece

Product Details:

- Locking Type Gravity locking / Clip on

- Features Heavy-duty construction, smooth trolley movement, easy installation, corrosion resistant

- Install Type Pre-assembled, quick mounting to I beam

- Usage & Applications Power cable and data cable support for cranes, hoists, or moving equipment

- Cable Type Flat / Round cable compatible

- Product Type I BEAM CABLE TROLLEY

- Length 4 Meter (m)

- Click to View more

X

I Beam Cable Trolleys Price And Quantity

- 450.0 INR/Piece

- 4 Piece

I Beam Cable Trolleys Product Specifications

- For standard I beam size 75mm to 150mm

- Galvanized Steel / Mild Steel

- 4 Meter (m)

- Power cable and data cable support for cranes, hoists, or moving equipment

- Other

- I BEAM CABLE TROLLEY

- Pre-assembled, quick mounting to I beam

- Silver

- Heavy-duty construction, smooth trolley movement, easy installation, corrosion resistant

- Flat / Round cable compatible

- High Voltage Volt (v)

- Gravity locking / Clip on

I Beam Cable Trolleys Trade Information

- GODAWN

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- AS PER YOUR REQUIREMENT AND GUIDELINE

- All India

Product Description

Cable Trolley for I beam

We are leading manufacturer of All types of Heavy Cable Trolley for I Beam,T channel. Cable trolley used in cable management in moving machinery, crane winch, tower crane, conveyor, port crane, eot crane and moving machinery. We provide complete solution for cable management system & crane electrification system.

Effortless Installation and Smooth Performance

With a clamp-on mounting system, these cable trolleys enable quick and secure installation to the lower flange of standard I beams. The sealed ball bearing wheels ensure quiet, smooth travel along the beam, minimizing vibration and wear. Their pre-assembled design further simplifies the setup, making them an efficient choice for fast-paced industrial environments.

Engineered for Durability and Safety

Built from galvanized or mild steel, each trolley features a powder-coated or zinc plated finish for superior corrosion resistance. The four-wheel system, paired with gravity locking or clip-on options, provides enhanced safety and stability for heavy power or data cableseven in high-voltage applications. Their rugged construction is ideal for continuous operation in challenging industrial settings.

Versatile Cable Management across Applications

Compatible with both flat and round cables, these trolleys are perfect for supporting cables on cranes, hoists, or other moving equipment within factories and warehouses. The load capacity accommodates substantial cable runs, while their size and locking mechanism suit a range of beam dimensions, ensuring adaptability and consistent cable support wherever needed.

FAQs of I Beam Cable Trolleys:

Q: How do I install I Beam Cable Trolleys on my structure?

A: Installation is straightforward due to the clamp-on method; simply attach the pre-assembled trolley to the lower flange of an I beam measuring 75mm to 150mm in width. No special tools or extensive setup are required, making it quick and convenient for industrial users.Q: What types of cables can these trolleys support?

A: These trolleys are compatible with both flat and round cables, including power and data cables, and are designed to manage heavy cable loads required for cranes, hoists, or moving equipment in industrial environments.Q: When should I use a sealed ball bearing wheel trolley instead of a regular one?

A: Sealed ball bearing wheels provide extremely smooth, low-maintenance travel along the beam, making them ideal for applications where consistent, reliable movement and reduced friction are essentialsuch as in continuous or high-speed cable management systems.Q: Where are I Beam Cable Trolleys typically used?

A: They are widely used in industrial facilities like factories, manufacturing units, and warehouses, particularly as cable management solutions for overhead cranes, hoists, or any equipment requiring mobile cable support on I beam structures.Q: What benefits do the powder-coated or zinc plated finishes offer?

A: Both powder-coating and zinc plating provide robust corrosion resistance, extending the trolleys lifespan and reliability even in harsh or humid conditions, thereby reducing maintenance and ensuring safe cable management over time.Q: How does the gravity locking or clip-on mechanism work?

A: The gravity locking or clip-on system securely attaches the trolley to the beam, preventing accidental disengagement during operation. This feature improves safety and stability, especially when handling heavy cables in dynamic industrial settings.Q: Are the trolleys suitable for high voltage environments?

A: Yes, these trolleys are engineered for high voltage applications, with insulation properties and construction suitable for safely conveying power cables under demanding electrical loads and varying operating temperatures (-20C to +80C).Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Crane Equipment' category

|

CMK ELECTRO POWER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |