- Home Page

- Company Profile

-

Our Products

-

Festoon System

- C Rail Festoon System

- C Rail System

- Cable Trolley

- Festoon system flat cable

- Rail Festoon System

- Festoon Flat Cable

- Crane Festoon System

- Heavy Duty Festoon System

- Festoon System Trolley

- Cable Festoon System

- Cable Rail Trolley

- crane C Rail System

- Crane C Track

- Heavy Festoon System

- Curve C Rail Festoon System

- C-Rail Festoon System

- Festoon System

- Double Decker Cable Trolley

-

Busbar System

- Gravity Type Current Collector

- Copper Jointer

- Eot Crane Busbar System

- Heavy Conductor Crane Rail

- Busbar Jointer

- Insulated Shrouded Dsl Conductor Bus Bar

- Central Power Feed Kit

- Enclosed Busbar

- Dsl Busbar For Eot Crane

- Shrouded Dsl Busbar System

- Enclosed Conductor Rail

- Copper Shrouded Dsl Busbar System

- Jointless Bus Bar

- Shrouded Dsl For Crane

- EOT Crane Current Collector

- Bus Bar Connector

- Dsl Busbar Towing Arm

- Box Type Busbar System

- Current Collector 125a

- Box Type Busbar

- Copper Shoe With Cover

- Current Collector (60a To 125a)

- Pin Joint Shrouded Bus Bar

- Shrouded Bus Bar System

- Dsl Busbar System

- Track Coupler

- Aluminium Bus Bar System

- Bolted Joint Dsl Bus Bar

- Copper Conductor Bar

- Pin Joint Bus Bar System

- Overhead Crane Busbar

- Insulated Shrouded Dsl Conductor Bar

- Busbar For Eot Crane

- Resistance Box

- Current Collectors

- Pendant cable

- Crane Equipment

- Wire Rope Hoist

- Master Control

- STACKERS

- Crane Brake

- EOT Crane Limit Switches

- Crane Pendant Station

-

Radio Remote Control

- Tele Crane Radio Remote Control

- Crane Remote Control System

- Radio Remote Control for EOT Cranes

- Crane Radio Remote

- Wireless Radio Remote

- Crane Double Speed Radio remote

- Crane Wireless Remote Controller

- F24-12S Telecrane Remote Control

- Overhead Crane Remote Control System

- Radio Remote Control System

- F24-BB Radio Remote Control

- Joystick Remote

- F24-12D Wireless Remote Controller

- Radio Remote Control for Cranes

- F24-4S Wireless Remote Control

- Telecrane Radio Control

- F23-BB Radio Remote Controller

- Crane Radio Remote Control

- Radio Remote Control

- F24-60 Double Joystick Remote Control

- Hoist Radio Remote control

-

Festoon System

- E - Catalog

- Industrial Cranes

- Contact Us

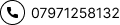

Busbar For Eot Crane

3630.0 INR/Meter

Product Details:

- Phase Three Phase

- Mounting Type Suspended / Surface Mounted

- Input Current Up to 1400A

- Protection Level IP54

- Humidity Up to 90% RH

- Efficiency High

- Condition New

- Click to View more

X

Busbar For Eot Crane Price And Quantity

- 100 Meter, Meter, Meter

- 3630.0 INR/Meter

Busbar For Eot Crane Product Specifications

- High

- Conducting and Delivering Electric Power

- New

- Electric

- Up to 1400A

- Power Transmission for EOT Cranes

- IP54

- Connector, Hanger Clamp, Joint Cover

- Three Phase

- Up to 90% RH

- Suspended / Surface Mounted

Product Description

Box Type Busbar

Busbar For Eot Crane

Due to our advanced production unit and a team of skilled professionals we are able to offer a wide gamut of Busbar for EOT Crane This crane is widely used for the electrification of mobile equipment The provided crane is designed using pristine class raw materials with the aid of progressive machinery under the stern guidance of skilled professionals In addition to this the offered Busbar for EOT Crane can be availed from us at reasonable rates

Key Points

- Supreme finish

- Easy to install

- Excellent durability

- Light in weight

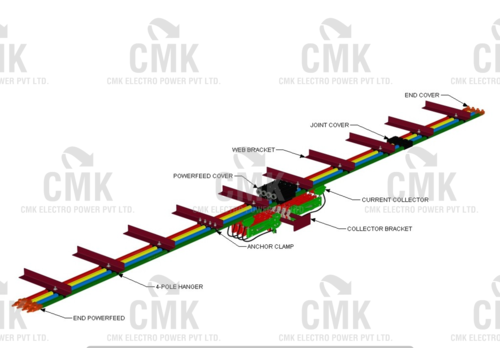

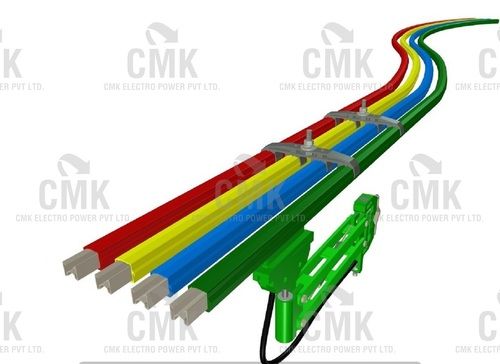

Superior Power Transmission for EOT Cranes

Designed to meet the stringent requirements of power transmission for EOT cranes, this busbar system combines high-quality materials with advanced engineering. Its robust construction ensures reliable electricity conduction even under heavy usage, making it a preferred choice for industrial crane rail operations. Excellent insulation properties, efficient current density, and color-coded busbars help maximize both safety and performance in demanding environments.

Customizable and Easy to Install

Available in standard 4-meter pieces, with custom sizes upon request, and multiple mounting options (suspended/surface mounted), this busbar adapts to various infrastructure needs. The connection choicesbolted or clampand included accessories like connector, hanger clamp, and joint cover streamline installation and maintenance. Efficient packaging in heavy-duty cartons or pallets ensures safe delivery and handling during setup.

Unmatched Safety and Longevity

Combining self-extinguishing PVC insulation and a powder-coated or anodized finish, the busbar provides outstanding fire and corrosion resistance. Meeting international IEC and IS standards as well as offering excellent humidity tolerance, it assures not just operational safety but also longevitydelivering reliable service for up to two decades in material handling environments.

FAQs of Busbar For Eot Crane:

Q: How does the busbar support safe power transmission for EOT cranes?

A: The busbar system uses high-quality PVC insulation and a rectangular design to safely conduct power. It features self-extinguishing covers and meets IEC 61439 and IS: 8623 standards, ensuring reliable electrical transmission with minimal risk in industrial crane operations.Q: What installation options are available for this busbar system?

A: The busbar can be installed either suspended or surface mounted, with bolted or clamp connection types. Standard lengths measure 4 meters, but custom sizes are also available to fit specific infrastructure requirements.Q: When should I consider customizing busbar dimensions or pole numbers?

A: Customizations are recommended when your crane rail or material handling equipment requires specific length, width, or pole numbers beyond the standard offerings. Custom designs enhance compatibility with unique layouts and operational loads.Q: Where is this busbar most commonly used?

A: This busbar system is primarily deployed in material handling equipment, crane rail systems, and EOT cranesespecially where safe and efficient electric power transmission is required in industrial environments.Q: What is involved in the busbar installation process?

A: Installation includes securing the busbar using supplied connectors, hanger clamps, and joint covers, followed by connection via bolted or clamp types according to your mounting preference. Heavy duty cartons and pallets facilitate safe handling during setup.Q: How does the busbar ensure long-term durability and operational safety?

A: Constructed from copper or aluminum and insulated with high-quality PVC, the busbar is powder coated or anodized for excellent corrosion resistance. Its self-extinguishing PVC cover provides reliable fire protection, ensuring a service life of 15-20 years.Q: What are the benefits of using this busbar for EOT cranes?

A: This busbar delivers high electrical efficiency, low power consumption, excellent safety (IP54 rating), and reduces maintenance due to its corrosion-resistant, fireproof design. It supports high current loads and is compatible with three-phase, 415V systems, optimizing crane operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Busbar System' category

|

CMK ELECTRO POWER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |